The cab is back on the road

Written on August 5th, 2023 by sudoyashi

First drive and I lost my throttle pedal!

So, I got too excited and didn’t check if my throttle cable stop was screwed down enough, it wasn’t lol. On my first official drive out with the new cooling system, I was going through the gears and my last mash of the throttle cable completely dropped my pedal. A clink clank later and I realized my throttle cable stop flew away, haha!

By a miracle, I found it up the street. Reinstalled it and carefully drove back home. Lesson learned: Don’t get too excited on your first drive. But who am I kidding, I just wanted to remember why I’m doing this haha.

Interior is cleaned up!

I made a rough ABS cover plate with mounting holes for the AEM gauge and the water temp gauge. These are 52mm openings, with some additional holes for wires and screws for the AEM gauge.

I’ve added a manual fan switch, similar to turning on the AC, but for the cooling fans. The thermoswitch is also hooked up as normal. I know the proper way is to have it all electronically controlled with sensors, but the gauge and fan switch gives me a lot of peace of mind with an older car.

I reconnected a loose ground for my oil pressure gauge’s backlight, so hooray I can see in the dark again.

I messed up with fuel pressure so I spent more money to fix it

I was… very frustrated lol with understanding fuel plumbing.

Initially, I bought a whole $200 AN hose kit to redo my whole fuel system, but later on, I decided to return most of the parts and just used a regular fuel hose because not all AN hose is made with PTFE! PTFE is the material resistant to gasoline’s corrosive properties. Without it, AN hose is just glorified rubber hose (for fuel). This isn’t a fuel-injected car so running the rubber hose that I have is going to be just fine. Carbureted applications don’t run much fuel pressure and after going through all of this, I returned almost everything and acted like it never happened.

Gone with the AN line plan and I decided to simply add a return line. Simple, right? I opened up the metal return line with a tiny metal hose cutter, the Ridgid tool was the perfect tool for the job because it was in such a hard to reach place. Then I used a -6 AN adapter to 5/16” hardline with a -6 AN to 5/16” barb end fitting.

Then, using the WIX 33040 fuel filter, I figured I could cobble a return line, but that’s not how return lines work. Return lines need a dedicated fuel pressure bypass/return regulator that will distribute fuel pressure correctly. So, since I lacked a bypass style fuel pressure regulator and that the second outlet on the WIX filter was not meant for a return, my fuel pressure practically went to 0! The extra port was not meant for a return line. For now, I removed it and the car ran okay after. That’s what you get for not spending the money on a real regulator. I reluctantly spent more money on a proper FPR which will be coming later in August.

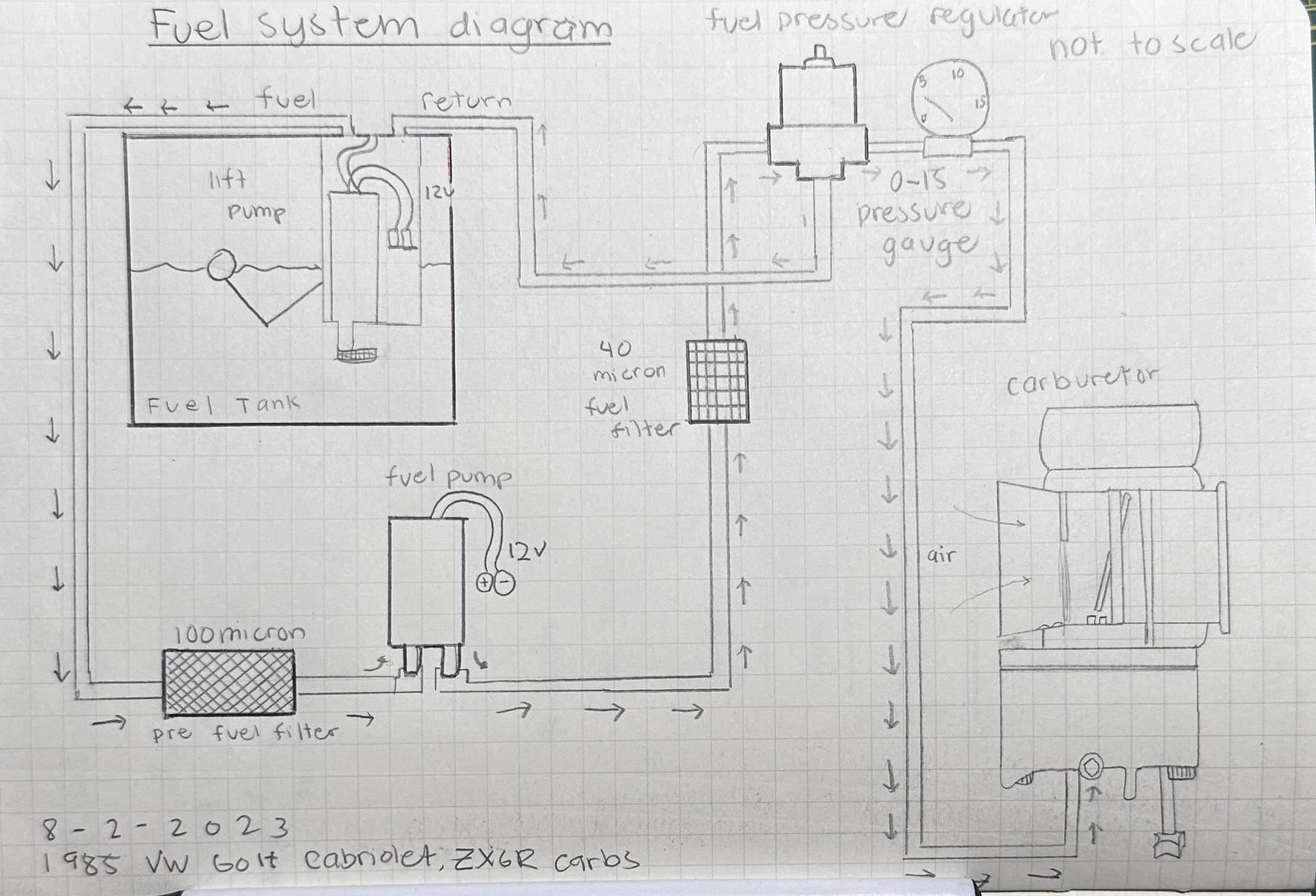

Ideal fuel system

The system assumes proper fittings where needed and 5/16” hose, comparable to -6 AN hose.

The fuel IN path is:

- Fuel tank lifter pump

- 100 micron fuel filter

- Fuel pump

- 40 micron fuel filter

- Fuel Pressure regulator, set 3 PSI

- Aeromotive Fuel Pressure Gauge, 1-15 PSI

- Carburetors

The fuel OUT or RETURN path is:

- Fuel Pressure regulator

- Factory return hardline to tank

In a diagram, this is what it looks like with the correct fuel fiilers.

Bad O-rings and the constant parts search challenge for an island

I was having a small fuel leak at the bowls and found out that my o-rings for my idle circuit went all crusty on me.

For those with idle circuit adjustment screws that also need new o-rings, I used 005 o-rings, this is the industry standard name. It is close to a 3/32” ID o-ring with a 7/32” OD. Funny enough, no one sold them on the island on Sunday! The smallest that I found at my local hardware and parts stores had 006 o-rings so I ordered them online instead and will install when it gets here.

In the meantime, past Josh stowed away some used o-rings I had which were still in decent shape. Until the new o-rings come in, I’ll hold off on refining the jet tune.

Don’t follow me, project cars suck lol.

I’ve lost about 5% bodyweight. My room and personal life went into a bit of disarray. I’ve been eating less. Less sleep. Everything just reminded me of finals week in college, lol.

Your time is worth a lot and with every project, you must consider your opporuntiy cost, the cost of money and time. Honestly, I’d love for someone else to do my work as long as I get to drive my car. There is a price to pay when you’re in a sprint to finish and complete a project and I’m lucky that this time it hasn’t consumed me. I’m proud of my work and I’m thankful I have the motivation and opportunity to do it, but my goodness this passion project really tests me, haha.

But you have to ask yourself, what do you really value? What can you afford? Do you really want this? If the answer comes clear for any of these questions, it’s a matter of logistics and planning. Everything is possible after that. But if you have doubts and question your motives and decisions, then reconsider why you’re doing something in the first place. The world becomes a place of sufferring the moment you don’t like it, but you’ll power through that sufferring when you decide figure out it’s important to you.

Everyone should find a project that is worth pushing their mental and physical abilities. Use it or lose it. We love to hate our projects, in the end, but at least my website will be proof it all happened. At the end of the day, when you do drive your project car. The pain is all but a memory… and then something else happens, haha.

Refuse to give up!